|

PDS have undertaken FEA structural analysis work on several LNG and other low temperature Storage Tank Design projects. Projects have included Dabhol LNG (Ratnagiri, India operated by GAIL & NTPC), Cameron LNG (Louisiana, USA), National Grid Grain LNG (Isle of Grain), Hazira Ethylene and Propylene (Reliance Industries), Sabic (Ethane, North Tees UK) and Dragon LNG (Milford Haven, Wales) |

|

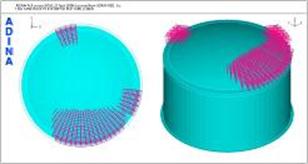

Outer concrete tank showing loads due to Platform locations. |

|

Outer concrete tanks at Dragon LNG Storage Tank, Milford Haven under construction |

|

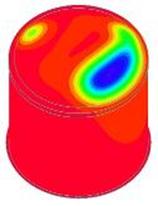

Plot of vertical displacements due above imposed Platform loads. |

|

Stress plot at the top of the concrete tank wall. Vertical, Hoop and Radial rebars are included. |

|

Structural FEA with Static/Variable Loading Conditions. Aspects considered include: - Critical loads ‘during’ construction (i.e short term) - Deadweights from structural components (e.g. Outer Tank Inner Tank, Insulation, Inspection Platforms etc) - Concrete shrinkage - Rebar (hoop, vertical, radial) prestress - LNG weight - Internal Gas Pressure - Soil settlement (Differential and Tilt) - Extreme and Operating Design temperatures conditions - Comprehensive and accurate modelling and simulation of Bottom Slab base heating - Complex Convection and Radiation boundary conditions - Wind / Snow loads - Explosive Blast loads / Missile impact - Seismic loads |

|

Structural Integrity FEA of Outer LNG Storage Tank due to Cryogenic Conditions Resulting from Inner Tank Failure. This analysis involves taking account of various Spill scenarios to determine the ‘liquid-tightness’ of the outer tank wall. Realistic modelling of concrete cracking is critical. Important features include: · Using a Concrete cracking (opening/closing/opening crack conditions) material model · Cracks are calculated and visualised so that they can be seen whether they are radial, hoop, vertical or complex · Determination of minimum Compression depths in concrete sections · Determination of crack widths · Other loads considered include Rebar prestress Seismic loads Component deadweights Gas Pressure |

|

Seismic FE Analysis. We have considerable experience in determining the effects of seismic loads (in combination with other loads) on different types of LNG tank structures. Scenarios include: · Scenarios include OBE and SSE loading conditions · Foundation, with Piling where appropriate, modelling included Soil Structure Interaction conditions modelled · Response Spectrum (modal analysis) and Time History analysis · Creation of secondary response spectra · Creation of Seismic Design Basis Specifications for Customers |

|

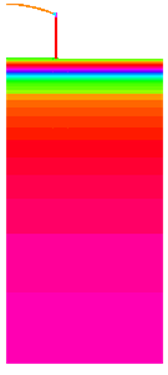

FE Models (Structural on LHS, Thermal on RHS) of Rock based Tank. Different colours indicate different materials and soil strata. Comprehensive analysis of Soil Settlement was undertaken. |

|

FE thermal model of Piled LNG Tank on LHS. On the RHS is shown a thermal map resulting from a Cryogenic Spill condition. |

|

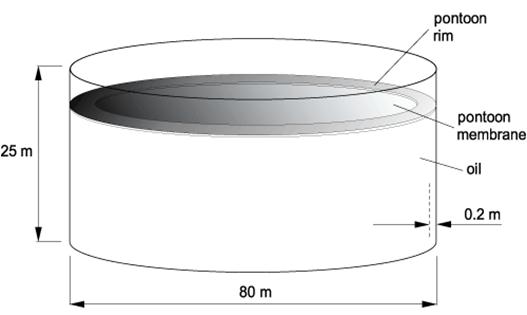

Fluid Structure Interaction to Analyse Sloshing in Large Tank

We present sloshing of oil in a tank with the tank base subjected to a horizontal ground motion. Sloshing in LNG tanks due to seismic loads has also been investigated.

This type of analysis can be very useful since results show that, in some case, traditional ’rule-of-thumb’ calculations can be overly conservative. A more realistic analysis can lead to substantial cost savings in the materials used.

Here the large flexible circular tank is filled with oil. A pontoon floats on the oil surface to prevent the oil from contacting the air. The tank is subjected to a horizontal ground motion of magnitude 1 metre and frequency 0.125 Hz. |

|

Analysis of Concrete Tank with Piles. In this project a natural convection air gap is also present between the ground and the underside of the concrete base. |

|

FEA / CFD Capabilities for Cryogenic Storage Tank and Low Temperature Storage Tank design include: · FEA Structural analysis with Static & Variable loading conditions (Construction and ‘In-Service’) · Thermal Mechanical Coupled loading · Soil Structure Interaction (SSI) with and without Piling · Cryogenic tank Fatigue analysis and low temperature storage tank Fatigue Analysis. Also analysis of other ageing mechanisms to determine possibility of extending design life of assets · CFD Stratification analysis resulting from differential densities when tank filling leading to pressure increases. · Sloshing (Shipping and on-land Tanks) analysis using CFD and Fluid-Structure-Interaction · Thermal analysis due to Boil-Off (BOG) used in conjunction with Structural analysis · Structural integrity of Outer tank (taking in to account Concrete cracking) due to Cryogenic conditions resulting from Inner Tank failure. Seismic loads also taken in to account in FEA · FE Modal analysis (e.g. for seismic and secondary response spectra purposes) · Seismic (Operating Basis and Safe Shutdown Earthquake) loads in combination with other loading conditions and Soil Structure Interaction (SSI) condition · Structural integrity of Ancillary equipment (e.g. roof platforms, process pipework and suspended decks) through loading from secondary response spectra determined from seismic analysis · Tank Sloshing effects in combination with other load conditions · ‘Localised’ FE analysis e.g. stress concentrations caused by inspection windows · Fires adjacent to Tanks |

|

Lateral displacement caused by Blast loads. Due to symmetry half model is sufficient. |

|

Tel: +44 (0)121 703 9236 or e-mail: info@pdslimited.com © Copyright Product Development Services Ltd. All rights reserved 2012 |

|

Additional Capabilities & Services for Cryogenic Storage Tanks and Low Temperature Storage Tanks · Fitness-For-Service (FFS) assessments to API 579/ASME FFS · Analysing ageing material damage mechanisms such as Low Cycle Fatigue analysis (LCF) for a range of cryogenic storage tanks and low temperature storage tanks. These include LNG tanks, Ethylene tanks and Propylene tanks. · Leak-Before-Break (LBB) assessment and Fracture Mechanics analysis · Analysing other material damage mechanisms such as brittle fracture, stress corrosion cracking and creep effects · Determining effects of localised damage. For example from dents, gouging and wall thinning · Investigation and simulation of Concrete creep · Fluid Structure Interaction with CFD / Fluid and Potential Elements · Creation of Design Basis (Technical Requirements) Specifications for Customer · Independent ‘Auditing’ service of Third party’s structural analysis · Worked directly from original Geotechnical Reports and with sub-contractors · Experience on other Power related jobs (e.g. for International Power, npower). This included Substation failure investigation / analysis. Also retrofit engineering to determine suitability of upgrading substations |

|

For clarity the fluid and solid parts are shown separately. The fluid is modelled in ADINA as a Navier-Stokes fluid using 3-D fluid elements with 4-node shell elements are used to model the flexible tank wall and the pontoon. The meshes are shown below. |

|

ADINA’s capability in accurately simulating cracking in concrete is critical in LNG Storage Tank design. The crack prediction plots below show various stages and forms of cracks in the base, wall and roof of an LNG Tank. |

|

The left plot shows the complete concrete tank with cracks shown by the red indicators. The other two plots are close-ups as shown. The circular indicators show hoop (circumferential) cracks. The ‘parallel line’ indicators show cracking that develops ‘normal’ to these lines. The red indicators show ’open’ cracks. There are some blue indicators which show ‘closed’ cracks ie cracks which had developed but, which have been closed up due to changes in loading conditions. |

|

INDUSTRIES |

|