|

The structure is subjected to electromagnetic forces, caused by the current in the superconducting coils, and loading due to the pre-tensioned bolts.

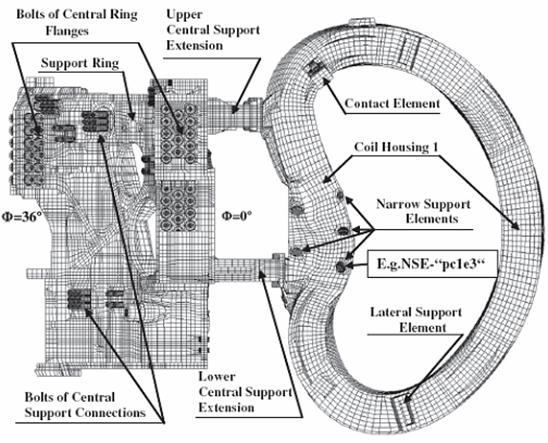

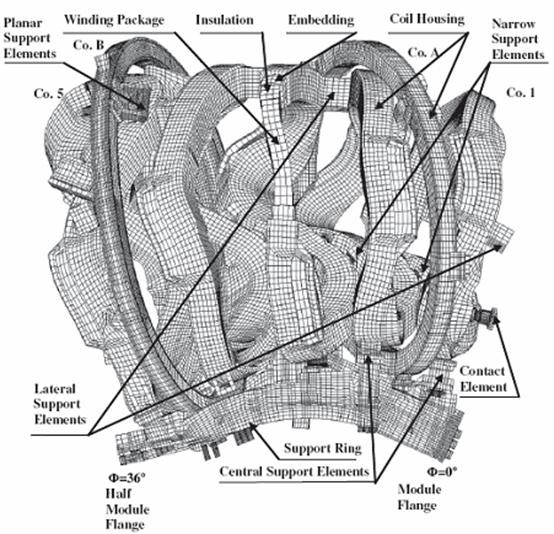

The FEA model consists of about 6 million DOFs, more than 120,000 contact segments and about 950 bolts.

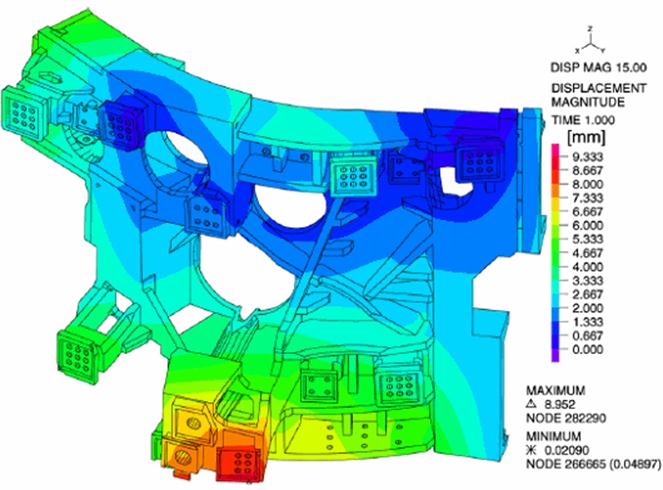

The FEA was performed in two steps. In the first step, the bolts were tightened; here the bolt forces were gradually increased to their final values. Then, in the second step, the electromagnetic forces were applied. Figures 4 and 5 show results for the bolt-tightening step, while Figures 6 and 7 show the deformations after the electromagnetic forces were applied. |

|

Figure 1 Finite element model of the superconducting coil and its support structure |

|

Figure 2 Finite element model of the superconducting coil |

|

Figure 3 Finite element model of the support structure |

|

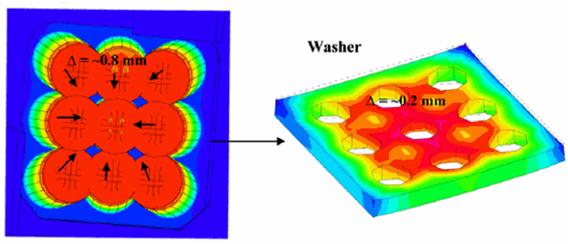

Figure 4 Displacement contour plot of bolt heads and washer due to the bolt tightening |

|

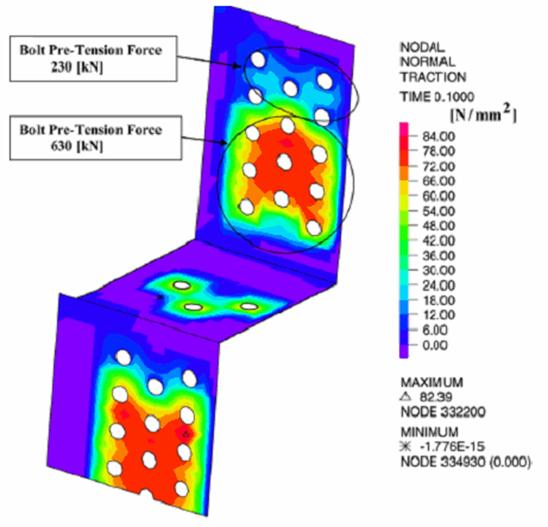

Figure 5 Contact normal tractions at the center of the support ring after the bolt tightening |

|

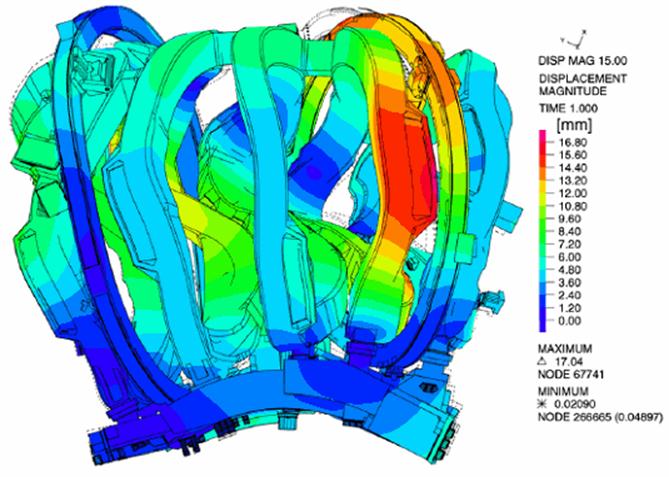

Figure 6 Displacement contour plot (coil) |

|

Figure 7 Displacement contour plot (support structure) |

|

FEA of the Bolted Assembly of the World's Largest Superconducting Coil

We show here some structural FEA results of the superconducting coil of the Wendelstein 7-X, the world's largest plasma fusion experimental device of the stellarator family.

In particular, we are looking at the connection of the coil to its support structure (see Ref.). The FEA, design and fabrication of the device are undertaken by the Max Planck Institute for Plasma Physics, Garching, Germany.

Portions of the coil and the support structure are shown in Figures 1 to 3 and the movie above. Due to the symmetry of the geometry and loading, only 1/10th of the total structure is modeled. Special symmetry boundary conditions are applied to the boundaries using the constraint equations available in ADINA FEA. The model mainly consists of 3D solid elements. Also, a number of beam elements are used to model bolts. |

|

Tel: +44 (0)121 703 9236 or e-mail: info@pdslimited.com © Copyright Product Development Services Ltd. All rights reserved 2012 |

|

INDUSTRIES |

|