|

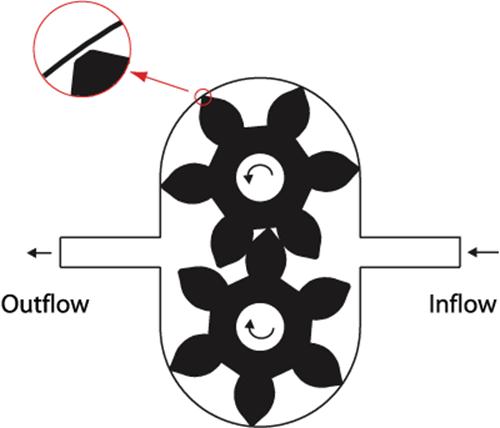

ADINA Fluid Structure Interaction is used extensively in the analysis of Gear Pumps. The Gear Pump in this analysisis shown in Figure 1. In this case, the pump was modelled and analysed in two dimensions. The fluid flow is driven by the two rotating gears, and the fluid mesh needs to be regenerated from time to time. In this Gear Pump analysis, remeshing was automatically performed many times per cycle. The movie above shows the velocity vector plot. Figure 1 shows a schematic of gear pump taken from the ADINA User Interface. Also shown is also the tiny gap between the gear teeth and the casing. |

|

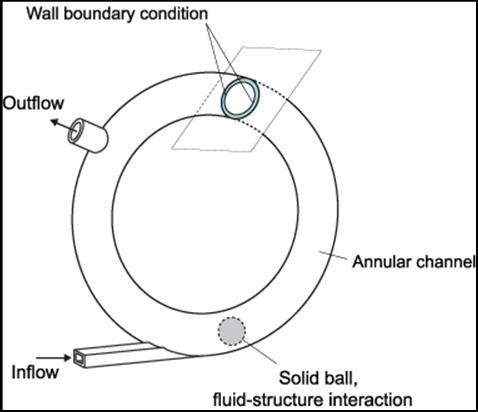

In the second analysis, a Flow Meter analysis is performed. The Flow Meter analysed is shown in Fig 2 and was modelled in 3D. In this Fluid Structure Interaction analysis, a solid ball is pushed by the fluid and travels along an annular channel. For the finite element model to have valid fluid elements during the analysis, the fluid mesh has to be regenerated while the ball is moving. Figure 2 shows the model geometry, and the velocity and pressure plots are shown in the movie. |

|

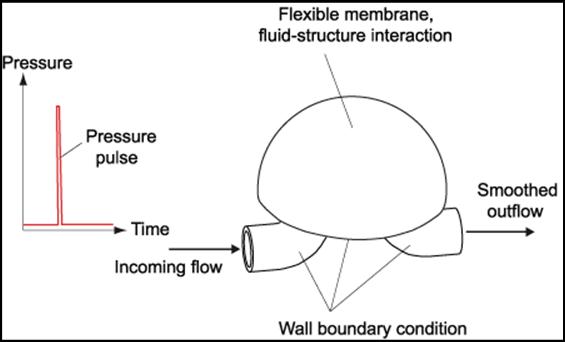

In this analysis, a Pulse Damper was modelled in 3D as shown in Figure 3. In this type of Pulse Damper analysis, an incoming flow fluctuation is dampened and smoothed to prevent large pressure jumps, thereby protecting the pipe system.

In this Fluid Structure Interaction the flexible structure boundary, and hence also the fluid domain in the damper, deform due to the incoming pressure pulsation.

During the analysis, even though the fluid elements are valid all the time, the mesh was regenerated in some time steps to maintain the desired element size. |

|

Fig 1 |

|

FSI Analysis of Gear Pumps |

|

Tel: +44 (0)121 703 9236 or e-mail: info@pdslimited.com © Copyright Product Development Services Ltd. All rights reserved 2012 |

|

Here we show the analysis of Fluid Structure Interaction problems through our Steered Adaptive Meshing (SAM) capability. The Steered Adaptive Meshing capability is an additional powerful tool in ADINA for modelling FSI applications with large deformations. Running automatically, the scheme makes these analyses easy and convenient for the ADINA user. |

|

FSI Analysis of Flow Meter |

|

Fig 2 |

|

FSI Analysis of Pulse damper |

|

Fig 3 |

|

INDUSTRIES |

|